Electrochemical hydrogen separation technology (EHS) offers a cost-effective way to produce high-purity hydrogen from local resources.

According to the federal government’s current plans, Germany should be climate neutral by 2045. One building block for achieving this goal is the National Hydrogen Strategy, which is supported by five federal cabinet ministries. Together they provide millions in state funding. The electrolysis output for the production of hydrogen in Germany is to be expanded to 10 gigawatts by 2030.

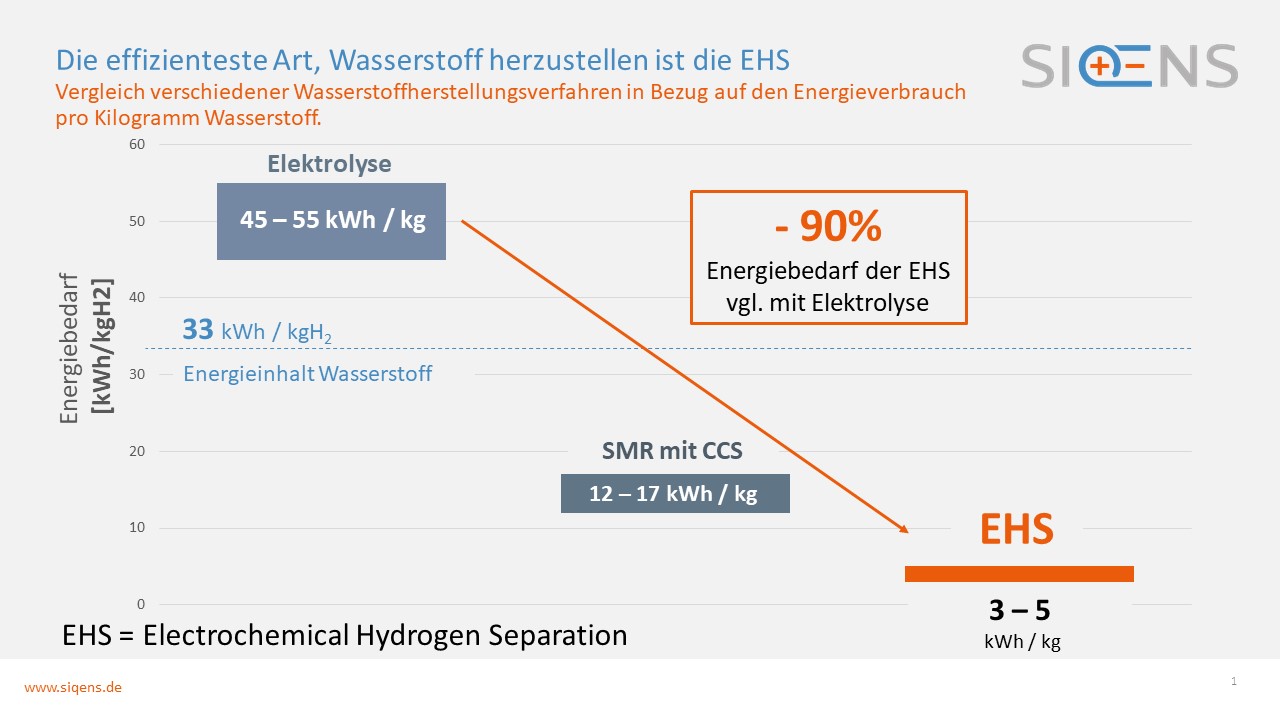

The hydrogen economy currently uses several processes to produce hydrogen. Steam methane reforming (SMR) is currently the most widespread. Around 98% of hydrogen is currently produced using the SMR process. However, the production of this so-called “grey” hydrogen produces CO2, which can be separated using carbon capture and storage (CCS) technologies. Then the “gray” becomes a “blue” hydrogen. To produce 1 kg of hydrogen, which contains 33 kWh of energy, the SMR process requires an energy expenditure of around 12-17 kWh.

“Green” hydrogen, on the other hand, is created through electrolysis, provided the electricity used was generated from renewable energies. However, the energetic balance of the process is sobering. Around 50 kWh are required to produce 1 kg of hydrogen using an electrolyzer, i.e. 50% more than is ultimately contained in the hydrogen. In addition, electrolysis has been on the market for a long time – its technical efficiency is therefore considered to be exhausted in expert circles.

EHS – Cost-effective technology with future potential

Electrochemical hydrogen separation technology (EHS), which was developed by the Munich company Siqens, offers a significantly more economical method for producing hydrogen. The EHS enables the local production of fuel cell quality hydrogen. For example, hydrogen is obtained by separating it from natural gas after transport via the existing gas infrastructure. But other locally available renewable resources such as biogas, methanol or methane can also be used. They all contain hydrogen atoms chemically bonded to carbon, oxygen and other atoms. In principle, it is even possible to obtain hydrogen in this way from waste streams, such as biomass and non-biogenic municipal and industrial waste. The EHS process still allows hydrogen to be extracted from natural reservoirs. Depending on the volume of hydrogen concentration in the feed gas, the energy requirement to produce 1 kilogram of hydrogen with EHS is only 3-5 kWh, i.e. around a tenth of the energy content of hydrogen. The EHS process reduces the energy requirement by around 90% per kilogram of hydrogen compared to electrolysis.

“Electrolysis requires a lot of electricity and is also expensive and complex,” comments Siqens CEO Dr. Thomas Klaue the cost comparison. “This once again underlines the need to use alternative technologies such as the EHS.” Together with a reformer connected upstream, the EHS can separate and separate the initially molecularly bound hydrogen from feed gases such as biomethane.

“Electrochemical hydrogen separation is the answer to the central challenges of a cost-effective hydrogen infrastructure, such as decentralized hydrogen production or the development of unused hydrogen resources,” says Klaue, summing up the economic advantages of the process.

About Siqens:

SIQENS, founded in Munich in 2012, develops and produces methanol fuel cells. The devices are used to provide emergency power to critical infrastructure and in places without a permanent connection to the power grid.

The SIQENS Ecoport fuel cell system is operated with liquid, easily available methanol. Hydrogen is produced from the methanol in the Ecoport. This reacts with oxygen in the SIQENS stack and generates electrical energy. Combined with a battery that the Ecoport automatically recharges when necessary, an EcoCabinet is created as a reliable power source.

In contrast to diesel generators, fuel cells are economical, require little maintenance and emit neither particulate matter nor nitrogen oxides as well as significantly reduced CO2 emissions. Methanol from renewable sources even enables completely climate-neutral operation.